Xinnovis Factory Mfc-500 Explosion Proof Gas Mass Flow Controller Equipped With Special Host Computer

Inhouse product

-

G2000 Women Belted Dress

$53.90

The perfect combination of a new generation of industrial-grade flow sensor chip and advanced gas circuit structure

The S500 series products adopt the industrial-grade advanced flow sensor chip independently developed by the company, combined with the low-voltage loss gas circuit structure, high-speed digital processing circuit and temperature compensation algorithm, and can realize the rapid control of gas flow within the minimum 0.1sccm and maximum 200slm flow range. Each product is subject to strict temperature compensation, and the error is less than 1% within 0-50 ℃. The product can be equipped with touch screen and independent power supply port, which is perfectly suitable for various application environments such as semiconductor, vacuum coating, laboratory, photovoltaic, analyzer, laboratory, etc.

Advantages

S1 Dual screen display

S2 Support range adjustment

S3 Quick response

S4 High precision

S5 Equipped with special host computer

S6 Certified product

|

Parameters |

|

|

Requirements |

Clean,dry and non-corrosive |

|

Gas type |

Air,N2,O2,Co2,He,H2,CH4,Ar,etc. |

|

Full scale |

(0-10,20,50,100,200,500)sccm (0-1,2,5,10,20,50,100,200)slm |

|

Accuracy |

0.3%F.S (≤30%F.S.) 1.0%S.P.(>30%F.S.) |

|

Range ratio |

100:1 |

|

Response time |

≤0.5s |

|

Repetition accuracy |

±0.2%F.S. |

|

≤20sccm,0.001sccm ≤100sccm and>20sccm,0.01sccm ≤1000sccm and>100sccm,0.1sccm ≤50slm and>1000sccm,1sccm >50slm,0.001slm |

|

|

Leakage rate |

1*10^9pa m³/s He |

|

Max.withstand pressure |

9.8bar |

|

Environmental requirements |

|

|

Operating temp. |

0-50℃ |

|

Operating humidity |

10%~90%R.H.(No ice or frost) |

|

Operating pressure |

≥2slm,0.5-4bar <2slm,0.5-6bar (Specific range related) |

|

Storage temp. |

-20~85℃ |

|

Electric parameters |

|

|

Power voltage |

DC24v |

|

Power consumption |

≤4.0w |

|

Starting time |

<1s |

|

Communication interface |

|

|

Interface type |

D-SUB9,RJ45 |

|

Analog control |

0~5v or 4~20mA |

|

Digital control |

RS485 or RS232 |

|

Digital signal(RS485) |

|

|

Interface type |

D-SUB9,RJ45 |

|

Traffic rate |

9600,38400,115200(Default)(can be modified through command or upper computer) |

|

Protocol |

Modbus-RTU (Private protocols can be customized) |

|

Equipment Address |

1(Default)~99 (can be modified through command or upper computer) |

|

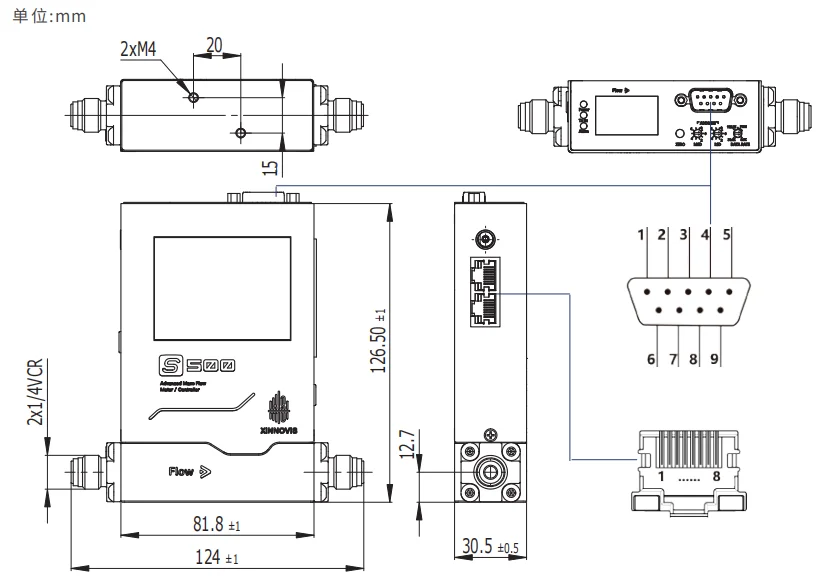

Mechanical parameters |

|

|

Connector type |

Card sleeve: 1/4inch VCR:1/4inch Others are optional. |

|

Gas connect material |

316L Stainless steel, FKM rubber,Si,SiO2,Silica gel |

|

Main material |

Foundation:316L Stainless steel Shell:Aluminum alloy |

|

Sealing material |

FKM rubber |

|

Weight |

0.95kg |

Website: http://en.xinnovis.com/

Qingdao Xinnovis Microsystem Technology Co., Ltd. is a high-tech enterprise specializing in industrial intelligent sensor chip design, module development, and high-end metering instrument R&D, manufacturing and sales. The company is located in Qingdao International Innovation Park, Laoshan District, Qingdao, adjacent to Shandong University (Qingdao Campus), Ocean University of China, Beihang Institute of Microelectronics, Lanhua Institute of Chinese Academy of Sciences (Qingdao), Qingdao University and other famous universities.

At present, the company focuses on the research and development, manufacturing and sales of gas flow measurement and control chips and modules such as industrial-grade gas flow sensor chips, high-end gas mass flow meters (MFM), mass flow controllers (MFC), and miniature digital anemometers. Through joint strategic partners, it has the world's first-class sensor wafer manufacturing capabilities, and has a 9,000-square-meter packaging and testing workshop, with IS09001, IS014001, 1ATF16949 and other quality management and manufacturing certifications. Related products are widely used in special gas fields such as semiconductors, gas analyzers, brazing/argon arc welding, metrology institutes, laboratories, etc., as well as civil fields such as building ventilation and automobiles. At the same time, the company provides solutions and technology development services for low-power dedicated smart sensors through cooperation with domestic artificial intelligence chip design companies.